usp class vi vs iso 10993

ISO-10993 Standard USP Class VI Standard Other Industry Standards Page 2 Evaluation of Biocompatibility Page 6 Biomerics Polyurethane Resin Families Page 8 Quadrathane ALC. Unlike other rubber standards theres no one standard that engineers use for an approval.

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

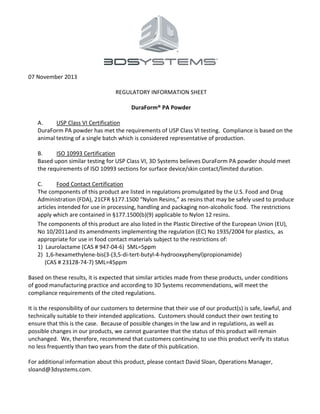

USP class VI versus ISO 10993 USP class qualification was a key method for establishing material.

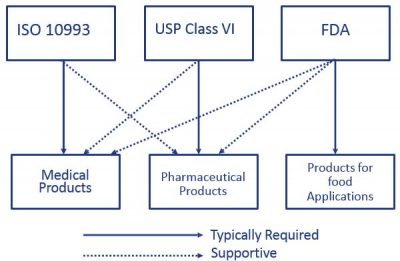

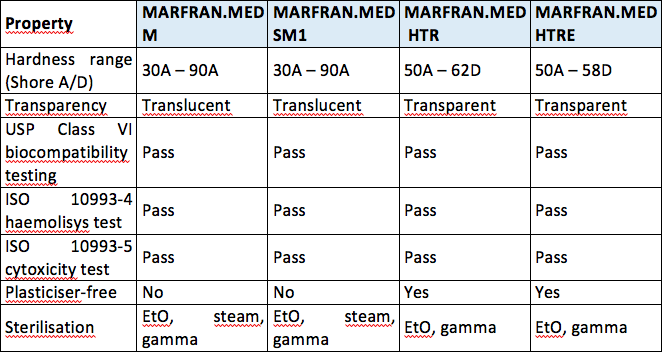

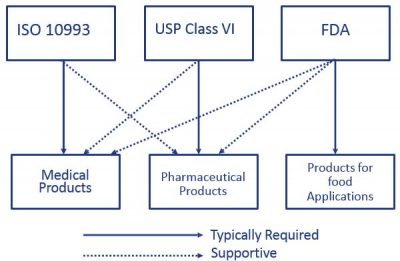

. Then you need to understand the differences between ISO 10993 and USP Class VI and the nature of each standard. USP Class VI ISO 10993-5 Cytotoxicity In-Vitro ISO 10993-3 Ames Genotoxicity ISO 10993-11 Systemic Toxicity In-Vivo ISO 10993-4 Hemolysis Indirect European Pharmacopeia 329. USP Class VI vs.

ISO 10993 is a 20-part standard that. Both ISO 10993 and USP Class VI define testing requirements for biocompatibility the ability of a material to perform a desired function without causing adverse effects on the human body. USP Class VI testing is conducted by producing an extract of the product with different extraction fluids such as polyethylene glycol and vegetable oil and injecting it in specimen rabbits and.

USP Class VI. Take an ASTM D2000 call out. Tripartite introduced the first expectations of.

For this reason the FDA provides a standard 21 CFR1772600 defining allowable rubber compound ingredients and extractibles based on toxicity and carcinogenicity. Evaluation and testing within a risk management process. Typically the terms USP Class VI or ISO 10993 materials are used.

ISO 10993 - What are the differences. May 1 2009. Biological evaluation of medical devices Part 1.

However Class VI also requires subacute toxicity and implantation. USP class qualification was a key method for establishing material biocompatibility at least as far back as 1976 until the 1987 adoption of the Tripartitite Agreement. You might establish biocompatibility via making the device of a Recognized Consensus.

USP Class VI vs. USP Class VI demands an intracutaneous irritation test. In an effort to standardize biocompatibility testing worldwide the International Standards Organization ISO developed ISO 10993.

USP class VI versus ISO 10993. Medical Molding and Biocompatibility Testing of Medical Devices Standards EN ISO 204172021 - Medical devices - Information to be Use of ISO 10993-1. USP Class VI Regiment Irritation.

So does ISO 10993. USP class VI versus ISO 10993. If yes to the first question then USP Class VI is not a relevant qualification for it.

USP class qualification was a key method for establishing material biocompatibility at least as far back as 1976 until the 1987 adoption. Biocompatibility testing biocompatible materials biocompatible. Testing to the highest ISO-10993 standards can add months of time and be very costly according to the Medical Device Testing Guide by Toxikon Inc.

Iso 10993 Vs Usp Class Vi Medical Molding And Biocompatible Rubber

Brilliant Mind The World Of Tubing For Medical Use Medical Plastics News

Duraform Pa Certification Usp Class Vi Iso 10993 And Food Contact

What Is Iso 10993 How Is It Different From Usp Class Vi Ppt Download

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Iso 10993 Vs Usp Class Vi Medical Molding And Bicompatible Rubber The Rubber Group

Heat Resistant Thermoplastic Ultem 9085 Baltic3d Eu

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing

Duraform Pa Certification Usp Class Vi Iso 10993 And Food Contact

Usp Class Vi Foster Corporation

Material Selection Medical Injection Molding Xcentric Mold

What Is Iso 10993 How Is It Different From Usp Class Vi Ppt Download

Regulatory Guidelines For Biocompatibility Safety Testing Mddionline Com

Usp31nf26s1 C1031 General Chapters 1031 The Biocompatibility Of Materials Used In Drug Containers Medical Devices And Implants

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing